THE MANUAL PROCESS OF PRINTING ON T-SHIRT

I will be showing you the steps involve in printing on t-shirt manually. The manual process of printing on T-Shirt involves the use of screen. I will be using the terms common among Nigerian Local practitioners, so do not crucify me if I’ve decided not to be professional. You don’t have to be scared because it is fun doing this. Printing on t-shirts is a good and lucrative business that can fetch you a fortune as a sole owner if you have a great marketing skill. Feel free to ask me any question at the end of this tutorial and I will gladly answer. I won’t waste much of your time writing unnecessary stories; and will love to do it in the Steve Jobs way: picture create unforgettable image in the memory.

Printing on T-shirts can be done manually as follows

Materials needed are:

1. The Screen: The screen is just a square or rectangular wooden frame with a special fabrics laid and tightened to cover a side of the frame just like a sieve. The fabrics use for a screen is either fine or open mesh.

The fine mesh is a fabric which has a tighter threading and often identified by its Yellow colour (yellow dyed).

The open mesh is more transparent and always white in colour (un-dyed).

You can buy the fabric separately and design your frame to build the screen yourself or save yourself the stress and buy the already made screen.

Some terms are chosen as standard amidst the Nigerian practitioners. When you are in Rome you act like the romans, if you chose to behave as non-Roman you’ll be treated as a stranger.

Therefore, if you are purchasing already made screen from the Nigerian shops you are to request for “A Mesh” (cost ₦300 – ₦500) depending on size. But the fabric is sold less than 500 per yard

· If you are to purchase fine mesh just request for a “Yellow mesh” while Open mesh is known as Open mesh.

· The Open mesh is often used for printing on fabrics because it is less tight, hence thicker (more) ink deposit.

The fine mesh is used for printings that require thinner ink deposit on substrate (surface) because it has tighter and thicker thread (e.g. prints on polymer, Umbrella etc.)

2. Squeegee: The squeegee is used in coating the surface of the mesh with Photo emulsion chemical as well as applying the ink on the substrate by dragging it on the mesh when the ink is applied in readiness for printing

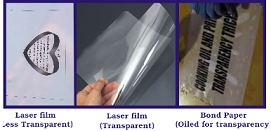

3. The Artwork and Film positive: The art work in modern context is simply the graphics design of work to be printed, designed on graphics software Application such as Corel draw and printed on a bond paper, Laser film (not so transparent) or Inkjet film(very clear and Transparent).

Don’t worry yourself if you are not good in computer graphics or you do not own a computer and printer to do this, the Artwork design for screen printing can be contracted to specialists in graphics design at a cheaper rate (₦200 – ₦300).Also note that the Artwork must be a very dark printout.

4. Photo emulsion and sensitizer: the mixture of these reacts to light when mixed in the right proportion, the photo emulsion will only be active when the sensitizer is mixed with it.

This Mixture is simply known as Exposing chemical in Nigerian printing material sales shop. Remember that in Rome. .. You act like Romans.

When the surface of a mesh is coated with this chemical with the aid of Squeegee in a slightly or totally dark room or box, it is left to dry naturally (e.g Night till the next morning) or artificially using a dryer. It is then exposed to mild sunlight for short period of time after placing your Artwork on the screen and covering with a piece of dense (transparent) glass. The part which is transparent on the Artwork enables the Screen or mesh to see light and become hardened while the dark area will not see light and remain softened hence, when sprayed with water, the soft part washed out and create a stencil on the Screen or Mesh.

4. Screen printing ink: There are different types of graphic ink.

Heat cured solvent based, solvent based air dry ink, and Ultraviolet ink that has to be cured by an Ultraviolet reactor which is expensive to procure.

Solvent based Heat cured ink used in T-shirt

Plastisols (call it plastex when buying). Kerosene is the solvent for this

Texfax or seritex is another brand which is heat and air cured. Water is the solvent for this

solvent based air dry ink used in Tshirt prints

a brand known as Opic is an example of this

I assume you know what a solvent is

5. Teflon: is a very smooth polymer-textile material which is placed on printed shirt for drying of the ink through the use of an Electric Iron

6. Retarder or Thinner: Retarder is a solvent used in thinning the ink to reduce the viscosity. Also used in cleaning the mesh and other tools on completion of work

PROCEDURES

Step 1: Design your art work on the computer and get it printed on Laser film, inkjet film or bond paper. If printed on Bond paper for economical reason, you need to make it transparent by using baby oil or vegetable oil to rub it.

Note: You need to know the dimension of what is to be printed. It will be required for the design work.

Your printout must be very dark which implies the text on it must not be transparent when inspected through light.

Step 2: Get your clean mesh coated with the mixed chemicals at both sides in dark or slightly dark room or cupboard then leave it to get dried in the dark chamber (5 – 10 hours). You can use a dryer as well for an instant dryness.

Note: it must not get dried excessively; else the required result will not be gotten

The mixture must be close to green colour and must not see light from where you purchase it, If not close to navy green colour add very little quantity of sensitizer.

Step 3: Take it out of the dark chamber, place your Artwork or film positive on your mesh and place a glass on it, then to a light source (daylight/ sunlight or fluorescent light). Duration for exposure to light depends on the Intensity of the light and quality of the chemical mixture (Photo emulsion and sensitizer)

Note: It must not see light until you place your artwork on the screen.

The wrong mixture of the chemical might have been sold and will not get desired result even when you tried thousands of time.

Step 4: Remove the Glass and your Artwork then take the screen to a water source for a spray; in the absence of tap water source you can continuously spay the screen surface with cup of water.

The part which is not exposed to light washes out because it is not hardened. And you have a stencil created on the mesh

Step 5: Let the mesh get dried in readiness for use

Step 6: Open your container of ink, and place 3-5% ink thinner or retarder in it and stir well. It may be easier to mix in a separate container. Only mix as much ink as you need for the job at hand (make sure you make use of the right ink)

Get your squeegee and put it in your screen, leaning it against the back frame. Have your material you are printing stacked up next to you on your right side. Also have a place on your left to place the signs when you take them out of the press, keeping in mind they will be wet when they come out and cannot be stacked on each other. •

Put your first piece in place sliding into your guides pour some ink into your screen right in front of your squeegee. Flood coat your screen, in other words pull ink across the screen with very little pressure, (the screen is in the up position) you want to cover the screen with layer of ink, but not put enough pressure to push it all the way through your stencil. • Lower the screen and either push or pull (your preference) the squeegee across the piece you are printing, using enough pressure to clean the image area of ink. Immediately re-flood the screen with ink.

Step 7: pull your first piece you have printed out of the press and do a quick look over it. Place it in your drying area put the next piece in and repeat the print process and so on. •

Remember, if your ink is air dry you need to work at a quick pace and may need someone to assist. If your image is getting fuzzy or rounded on the corners your screen is drying, when this happens you need to clean only the image area from the bottom of the screen with thinner and then continue. If you are only getting a few prints and this keeps happening you may need to thin your ink more. •

If you are printing a multi-colour print, after the first colour is complete, completely clean the screen, squeegee etc. • Un-tape your bump guides, place the new screen in the press centred and this time set-up to one of the pieces that you have printed, again using the bump guides in the same places. • When you are done do a complete clean-up and store all your materials in a cool dry place.

Please, which ink is best for.printing.on jerseys

ReplyDeletesomeplace the content material of the weblog surrounded through little arguments. yes it's far wholesome for readers. they are capable of encompass this form of language in their writing talent similarly to on the same time as group dialogue in university. screen printing toronto

ReplyDeletesomeplace the content material of the weblog surrounded through little arguments. yes it's far wholesome for readers. they are capable of encompass this form of language in their writing talent similarly to on the same time as group dialogue in university. screen printing toronto

ReplyDeletethat is the number one time I came to this blog and i discovered a few applicable stuff proper right here. essentially I keen to realize new parameters of writing every-time and someday it turn out to be actually very tough to find such type of platform. embroidery near me

ReplyDeleteShare great information about your blog , Blog really helpful for us . We read your blog , share most useful information in blog . Thanks for share your blog here . Nocciole biologiche

ReplyDelete

ReplyDeleteVery good blog and nice information thanks for sharing..

web development companies in austin texas

austin web development company

Direct emulsion is a foundational method in screen printing—accuracy is everything. For expert services using industry-standard techniques, explore our screen printing solutions.

ReplyDelete